Crane Structures

Crane runways and structures can be engineered and fabricated to fit any of your crane needs. Crane support systems are designed to today’s CMAA standards. we are proud to say that our crane runways are constructed to maximize space, equipment life, productivity, and most of all worker safety . We can provide a number of useful and easy ways to fit a crane way into your existing space. Building supported runways and systems can be used when the loadings are included in the building design. This will allow for the runway girders and rails to be supported by the shelves or haunches off the building columns.

A ‘Free Standing Runway Structure’ could be used when the building’s design did not include the crane load. This requires more material but would not be attached to any part of the building while being able to resist the lateral and longitudinal forces that the crane would be generating. Some additional variations of this would be knee or header braced. For buildings that can permit extra capacity a Semi-Free Standing Runway could be a solution. The design would attach the columns and runways to the existing building which has potential to also cut down on cost for steel and other production needs. Knee and Header Braced Systems are great design options that require minimum floor obstruction and specified maximum hook height.

For a crane runway system that would be unobstructed by support columns the best solution would be a Ceiling Mounted Runway System or a Roof Structured Runway which bolts to the frame, trusses or can be hung from engineered suspension rods and tubes brackets.

Top Running Crane Runway

Designed more for the heavier lifting in the range of 20 tons or more, top running cranes are less flexible and more perplex to use. Top running crane runways are good for facilities that have low headroom, because the system moves above the runway which allows for extra headroom. A rail is installed on top of the runway beams, and the wheels ride on the rail rather than directly on the runway beams.

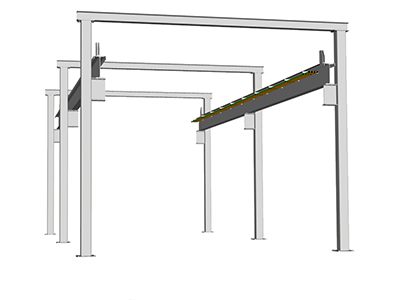

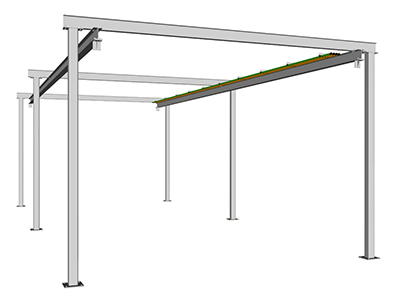

Free Standing Top Running Header Braced Runway Structure

The runway is supported by the free standing support columns each pair tied together by a header. Header braced systems are ideal when the lowest obstruction in the building is high enough that it does not limit the hook height. This runway type is easily expandable and can handle multiple bridge crane systems.

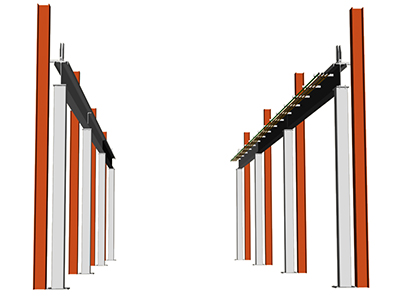

Facility Column Braced Crane Runway

When a new or existing building has enough reserve capacity to resist the longitudinal (along the length of the crane runway) and lateral (across the width of the runway) forces, MHiPros can attach the columns and runways to these buildings, reducing the amount of steel required to produce an overhead crane system.

Underhung Crane Runway

Generally a lot lighter than a top running system, under hung crane runways allows for more versatility usability. Underhung runways can be ceiling mounted because of being dramatically lighter. Also they have the ability to run side-by-side without interfering with one another. Another mechanical advantage that under hung crane systems have is that they can be interlocked together. By locking the adjacent ends of two cranes together an operator can transfer the load from one system to another. They can also interlock with monorails to allow for the transferring of material along a fixed path.

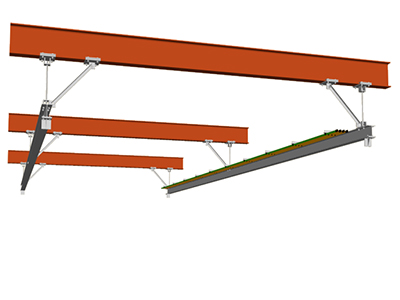

Ceiling Mounted Crane Runway

MHiPros underhung ceiling mounted runways feature overhead crane runways that attach directly to the ceiling or roof structure of a building. Ceiling mounted, underhung systems are extremely versatile and can be used to easily transfer loads from one bay to another with the use of transfer switches. Underhung ceiling mounted crane runways allow for utilization of entire floor space under the crane runway as well.

Free Standing Under Hung Header Braced Runway Structure

Braces to other support structures are not needed because the free standing design resists lateral and longitudinal forces on its own. Underhung runway systems are designed to support the stand alone workstation bridge crane from the lower flange of the runway girder. Underhung free standing bridge crane runway have the best overall hook coverage.

Follow Us