Overhead Bridge Cranes

Overhead bridge cranes are permanently installed cranes within a facility that are used to lift and move material from one location to another in a safe and efficient manner. The bridge crane provides lift coverage within its full dimensional envelope which typically prevents the need for multiple lifting devices or multiple transfers.

Overhead bridge cranes are typically designed and manufactured per application so that they can meet the exact needs of the user and fit within the facility’s dimensional parameters.

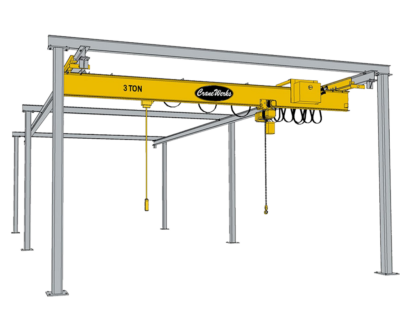

TOP RUNNING BRIDGE CRANES

- Capacities: ¼ ton to 20 ton+

- Sizes: Any width and length available

- Customized per application

Top Running Crane Runway systems are the workhorses of the overhead crane world. They consistently, reliably handle heavy loads, day-in-and-day-out. The Top Running Runway design affords maximum hook height.

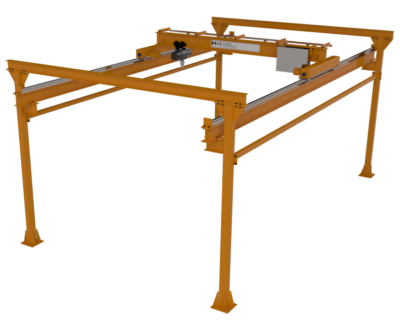

UNDERHUNG BRIDGE CRANE

- Capacities: ¼ ton to 20 ton+

- Sizes: Any width and length available

- Customized per application

Generally, a lot lighter than a top running system, underhung crane runways allow for more versatility and usability. Because they’re dramatically lighter, underhung runways can be ceiling-mounted. They also have the ability to run side-by-side without interfering with one another. Another mechanical advantage of underhung crane systems is their ability for multiple systems to be interlocked, enabling operators to transfer loads between them. They can also interlock with monorails, allowing for material transfer along a fixed path.

MOUNTING TYPES

HEADER BRACED

The runway is supported by the freestanding support columns, each pair tied together by a header. Header-braced systems are ideal when the lowest obstruction in the building is high enough that it does not limit the hook height. This runway type is easily expandable, and can handle multiple bridge crane systems