-

The Fold-Away Swing Arm Fall Arrest System is an excellent solution for facilities that require a foldable fall arrest system to provide protection while staying out of the way when not in use. This system is particularly useful in facilities where overhead cranes occupy the space or when maintenance is carried out in narrow bays without usable ceilings. The arms can be fully extended, offering workers a fixed path of rigid track fall protection, with the flexibility to travel up to 30 degrees off-center of the track. When not in use, the track and its arms can be conveniently folded against their support columns, leaving ample room for large overhead cranes. With standard track lengths ranging from 23 to 163 feet and support spacing distances of up to 50 feet, this system can span multiple work areas with ease, providing comprehensive fall protection coverage. Safety and reliability are paramount in this system, designed to accommodate a maximum person weight, plus tools, of up to 310 pounds when used with energy-absorbing self-retracting lanyards. Custom systems are available to cater to heavier workers up to 420 pounds. The Fold-Away Swing Arm Fall Arrest System offers convenient field assembly with bolt-together components, eliminating the need for welding. The enclosed track design ensures smooth and quiet trolley travel, reducing the possibility of dirt or dust build-up that might interfere with its movement. Meeting or exceeding OSHA and ANSI standards, this fall arrest system provides a secure and compliant solution for various work environments.

The Fold-Away Swing Arm Fall Arrest System is an excellent solution for facilities that require a foldable fall arrest system to provide protection while staying out of the way when not in use. This system is particularly useful in facilities where overhead cranes occupy the space or when maintenance is carried out in narrow bays without usable ceilings. The arms can be fully extended, offering workers a fixed path of rigid track fall protection, with the flexibility to travel up to 30 degrees off-center of the track. When not in use, the track and its arms can be conveniently folded against their support columns, leaving ample room for large overhead cranes. With standard track lengths ranging from 23 to 163 feet and support spacing distances of up to 50 feet, this system can span multiple work areas with ease, providing comprehensive fall protection coverage. Safety and reliability are paramount in this system, designed to accommodate a maximum person weight, plus tools, of up to 310 pounds when used with energy-absorbing self-retracting lanyards. Custom systems are available to cater to heavier workers up to 420 pounds. The Fold-Away Swing Arm Fall Arrest System offers convenient field assembly with bolt-together components, eliminating the need for welding. The enclosed track design ensures smooth and quiet trolley travel, reducing the possibility of dirt or dust build-up that might interfere with its movement. Meeting or exceeding OSHA and ANSI standards, this fall arrest system provides a secure and compliant solution for various work environments. -

- Custom heights, spans, cantilever design, and support structures

- Single, dual, or multiple tracks for use by one, two, or multiple users

- Intermediate bumpers can be used to limit trolley travel between the factory-installed end stops for any reason

- Curved track accommodates almost any degree curve

- Any color paint, epoxy coatings, or galvanized finish

- Mylar® lip seal for heavy dust or paint overspray applications

-

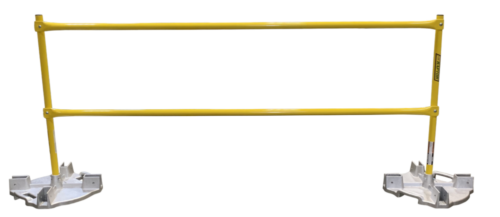

The Temporary Weighted Base Guardrail is designed exclusively for Fall Prevention applications. Fall Prevention Systems are strategically positioned along exposed edges to ensure workers are protected from falls and can serve as an alternative to Fall Protection or safety netting systems. It is crucial to note that Fall Prevention Systems should never be used for Personal Fall Arrest, Work Positioning, Climbing, Rescue, or any other systems. When installing this guardrail, it should be placed perpendicular to create a continuous run. To ensure system stability, outriggers must always be used at both ends of any interruption in the Guardrail System, as well as at both ends of a continuous Guardrail System. This additional precaution enhances the overall effectiveness and safety of the guardrail setup.

The Temporary Weighted Base Guardrail is designed exclusively for Fall Prevention applications. Fall Prevention Systems are strategically positioned along exposed edges to ensure workers are protected from falls and can serve as an alternative to Fall Protection or safety netting systems. It is crucial to note that Fall Prevention Systems should never be used for Personal Fall Arrest, Work Positioning, Climbing, Rescue, or any other systems. When installing this guardrail, it should be placed perpendicular to create a continuous run. To ensure system stability, outriggers must always be used at both ends of any interruption in the Guardrail System, as well as at both ends of a continuous Guardrail System. This additional precaution enhances the overall effectiveness and safety of the guardrail setup. -

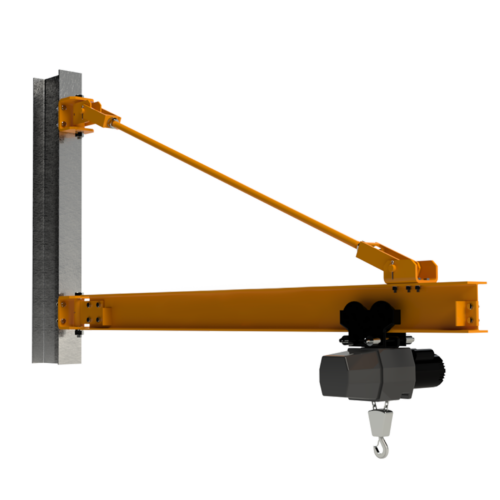

Highlighted Features:

Highlighted Features:- Capacity: Supports loads up to several thousand pounds

- Range of Motion: 180-degree rotation for efficient material handling

- Construction: High-strength materials with tie-rod support for stability

- Installation: Wall-mounted design for space-saving and easy installation

- Flexibility: Ideal for various industrial applications

- Safety: Reduces manual lifting and complies with OSHA standards

- Productivity: Improves efficiency in lifting and moving loads

-

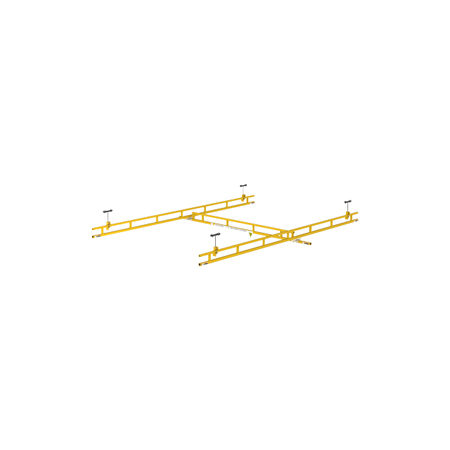

The Traveling Bridge Fall Protection System, an exceptional choice for larger maintenance applications, providing versatile fall protection across industries such as aircraft hangars, aircraft production facilities, transportation vehicle maintenance facilities, and industrial settings. This solution comes in both standard assembly kit and custom-engineered options, offering the flexibility of ceiling mounting to existing supports or bolting to the floor with freestanding support columns and headers. The Traveling Bridge system ensures unrestricted movement, empowering the trolley to effortlessly track the user in any direction (360 degrees) and effectively minimizing swing fall hazards when combined with a self-retracting lanyard (SRL). Its compatibility with overhead cranes and capacity to support virtually limitless track lengths using existing support steel provides a seamless blend of versatility and effectiveness for various work scenarios. Designed with safety and reliability in mind, the Traveling Bridge Fall Protection System accommodates maximum person weight, plus tools, up to 310 pounds when used with energy-absorbing self-retracting lanyards. Custom systems are available for heavier workers up to 420 pounds, providing a comprehensive fall protection solution for diverse workforces. The system boasts quick and simple field assembly with bolt-together components, eliminating the need for welding. Its enclosed track design ensures smooth and quiet trolley travel while minimizing the possibility of dirt or dust build-up that could interfere with its movement. Meeting or exceeding OSHA and ANSI standards, this fall protection system offers peace of mind and compliance assurance.

The Traveling Bridge Fall Protection System, an exceptional choice for larger maintenance applications, providing versatile fall protection across industries such as aircraft hangars, aircraft production facilities, transportation vehicle maintenance facilities, and industrial settings. This solution comes in both standard assembly kit and custom-engineered options, offering the flexibility of ceiling mounting to existing supports or bolting to the floor with freestanding support columns and headers. The Traveling Bridge system ensures unrestricted movement, empowering the trolley to effortlessly track the user in any direction (360 degrees) and effectively minimizing swing fall hazards when combined with a self-retracting lanyard (SRL). Its compatibility with overhead cranes and capacity to support virtually limitless track lengths using existing support steel provides a seamless blend of versatility and effectiveness for various work scenarios. Designed with safety and reliability in mind, the Traveling Bridge Fall Protection System accommodates maximum person weight, plus tools, up to 310 pounds when used with energy-absorbing self-retracting lanyards. Custom systems are available for heavier workers up to 420 pounds, providing a comprehensive fall protection solution for diverse workforces. The system boasts quick and simple field assembly with bolt-together components, eliminating the need for welding. Its enclosed track design ensures smooth and quiet trolley travel while minimizing the possibility of dirt or dust build-up that could interfere with its movement. Meeting or exceeding OSHA and ANSI standards, this fall protection system offers peace of mind and compliance assurance.

- 1 (877) 511-6353

- info@mhipros.com

- Locations