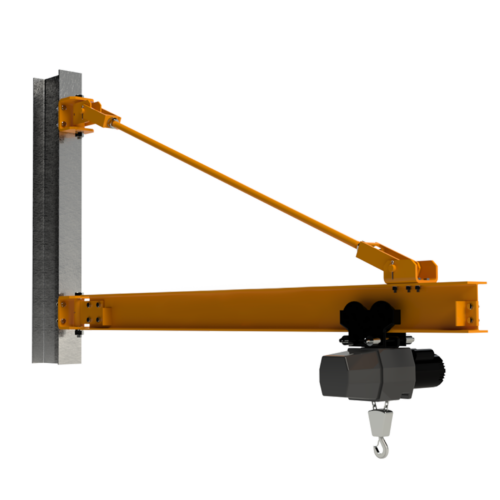

- Capacity: Supports loads up to several thousand pounds

- Range of Motion: Dual-arm design with two swivel points for enhanced maneuverability

- Construction: High-strength, durable materials for heavy-duty use

- Installation: Can be mounted on walls, floors, or columns

- Flexibility: Ideal for reaching around obstacles and into confined spaces

- Safety: Reduces manual lifting and physical strain on operators

- Productivity: Improves load handling efficiency and reduces downtime

Jib Cranes

A jib has a mast, cantilevered boom and can typically rotate 360°. The role of the jib is to support a movable hoist fixed to either a wall or pillar mounted on the floor.

-

Highlighted Features:

Highlighted Features: -

Highlighted Features:

Highlighted Features:- Capacity: Supports loads up to several thousand pounds

- Range of Motion: 360-degree rotation for maximum flexibility

- Construction: High-strength, durable materials for long-term use

- Installation: Mounts directly to existing concrete surfaces

- Flexibility: Easily relocatable within a facility

- Safety: Minimizes manual lifting and operator strain

- Productivity: Enhances load handling efficiency

-

Highlighted Features:

Highlighted Features:- Capacity: Supports loads up to several thousand pounds

- Versatility: Suitable for various industrial applications with adjustable reach

- Construction: Made from high-strength steel for durability and reliability

- Installation: Can be easily installed on concrete floors with a minimal footprint

- Flexibility: 360-degree rotation for maximum range of motion

- Safety: Reduces manual lifting and meets OSHA safety standards

- Productivity: Improves efficiency with smooth and precise load handling

-

Highlighted Features:

Highlighted Features:- Capacity: Supports loads up to several thousand pounds

- Mobility: Equipped with a portable base for easy relocation

- Construction: Made from high-strength materials for durability

- Versatility: Suitable for various industrial applications

- Flexibility: Adjustable height and reach for precise load handling

- Safety: Complies with OSHA standards to ensure a safe work environment

- Productivity: Improves efficiency with smooth, precise load handling

-

Highlighted Features:

- Capacity: Supports loads up to several thousand pounds

- Range of Motion: 180-degree rotation for efficient material handling

- Construction: High-strength materials with tie-rod support for stability

- Installation: Wall-mounted design for space-saving and easy installation

- Flexibility: Ideal for various industrial applications

- Safety: Reduces manual lifting and complies with OSHA standards

- Productivity: Improves efficiency in lifting and moving loads

-

Highlighted Features:

Highlighted Features:- Capacity: Supports loads up to several tons

- Range of Motion: 180-degree rotation for comprehensive coverage

- Construction: Robust, high-strength steel construction

- Installation: Mounts on walls or columns to save floor space

- Versatility: Suitable for tight spaces and low headroom areas

- Safety: Adheres to OSHA regulations, reducing workplace injuries

- Efficiency: Improves load handling and workflow

-

Highlighted Features:

- Capacity: Supports loads up to several hundred pounds

- Range of Motion: 360-degree rotation for maximum coverage

- Construction: High-strength, durable materials for industrial use

- Installation: Free-standing and portable designs for versatile placement

- Flexibility: Ideal for various tasks in industrial workstations

- Safety: Reduces manual lifting, adhering to OSHA standards

- Productivity: Enhances material handling efficiency and precision