-

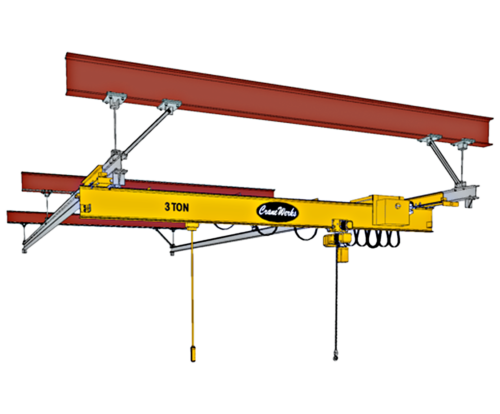

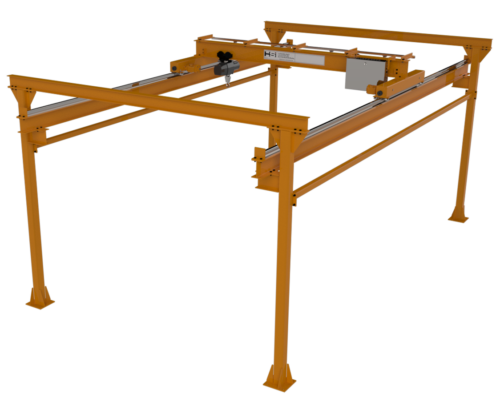

Overhead bridge cranes are permanently installed cranes within a facility that are used to lift and move material from one location to another in a safe and efficient manner. The bridge crane provides lift coverage within its full dimensional envelope which typically prevents the need for multiple lifting devices or multiple transfers. Overhead bridge cranes are typically designed and manufactured per application so that they can meet the exact needs of the user and fit within the facility’s dimensional parameters.

Overhead bridge cranes are permanently installed cranes within a facility that are used to lift and move material from one location to another in a safe and efficient manner. The bridge crane provides lift coverage within its full dimensional envelope which typically prevents the need for multiple lifting devices or multiple transfers. Overhead bridge cranes are typically designed and manufactured per application so that they can meet the exact needs of the user and fit within the facility’s dimensional parameters. -

- Crane Rotation: 360°

- Capacities: up to 5 tons on standard models; up to 10 tons custom

- Spans: up to 20’ standard; up to 40’ custom

- Heights: up to 20’ standard; up to 40’ custom (distance from floor to overhead support)

-

Spanco Mast-Style Jib Cranes provide full 360-degree rotation while eliminating the cost of a special foundation, which can cost more than the crane. As a lower cost alternative to freestanding jib cranes, these full-feature mast-style cranes:

Spanco Mast-Style Jib Cranes provide full 360-degree rotation while eliminating the cost of a special foundation, which can cost more than the crane. As a lower cost alternative to freestanding jib cranes, these full-feature mast-style cranes:- Are bolted to the floor and existing overhead support structure (e.g., steel beams)

- Require no special foundation, but only a standard 6-inch reinforced concrete floor

- Are available with power rotation on all models

Mast-Style Jib Crane Features

- Uses wide-flange beam or I-beam for the boom and a wide-flange beam for the column

- The top assembly has self-aligning spherical bearings

- The bottom assembly has bronze bearings and bronze thrust washers

- Both bearing assemblies are provided with grease fittings for lubrication to aid rotation

-

Highlighted Features:

Highlighted Features:- Capacity: Supports loads up to several thousand pounds

- Range of Motion: Dual-arm design with two swivel points for enhanced maneuverability

- Construction: High-strength, durable materials for heavy-duty use

- Installation: Can be mounted on walls, floors, or columns

- Flexibility: Ideal for reaching around obstacles and into confined spaces

- Safety: Reduces manual lifting and physical strain on operators

- Productivity: Improves load handling efficiency and reduces downtime

-

401 Series Wall-Mounted Articulating Jib Cranes

- Offers 360-degree rotation for outer arm and 180-degree rotation for inner arm

- Perfect for individual workstations where each worker needs complete access to one jib crane

- Outstanding headroom permits installation in tight locations and crowded shops

- Provides a clear work area with no floor obstructions and requires minimal overhead clearance for installation

-

402 Series Freestanding Articulating Jib Cranes

- Easy installation at nearly any location

- Offers 360-degree rotation for inner and outer arms

- Anchor bolts are used to secure the baseplate to a reinforced concrete foundation for ultimate stability under load

- The pipe mast’s connection to the hexagonal baseplate is reinforced with six equally spaced gussets

-

402 Series Portable Base Articulating Jib Cranes

- Easy installation at nearly any location

- Offers 360-degree rotation for inner and outer arms

- Anchor bolts are used to secure the baseplate to a counterweight base for portability and stability under load

- The pipe mast’s connection to the hexagonal baseplate is reinforced with six equally spaced gussets

-

Highlighted Features:

Highlighted Features:- Capacity: Supports loads up to several thousand pounds

- Range of Motion: 360-degree rotation for maximum flexibility

- Construction: High-strength, durable materials for long-term use

- Installation: Mounts directly to existing concrete surfaces

- Flexibility: Easily relocatable within a facility

- Safety: Minimizes manual lifting and operator strain

- Productivity: Enhances load handling efficiency

-

Spanco Foundationless Jib Cranes are industrial slab-mounted systems that are bolted to reinforced concrete. These systems do not require a special foundation, which can sometimes cost more than the system. By not requiring a special foundation, you don’t have to wait for concrete to cure, meaning you can have your system installed sooner. Spanco Foundationless Jibs can be installed almost anywhere within your facility and be easily relocated if needed.*Varies depending on HUB selected 605 Series Foundationless Workstation Jib Cranes

Spanco Foundationless Jib Cranes are industrial slab-mounted systems that are bolted to reinforced concrete. These systems do not require a special foundation, which can sometimes cost more than the system. By not requiring a special foundation, you don’t have to wait for concrete to cure, meaning you can have your system installed sooner. Spanco Foundationless Jibs can be installed almost anywhere within your facility and be easily relocated if needed.*Varies depending on HUB selected 605 Series Foundationless Workstation Jib CranesCapacities (Pounds) HUB (Feet) Span (Feet) 250 12 16 500 8-12 8-12* 1,000 8-12 4-8* - 360-degree rotation

- Enclosed track protects the hoist trolley from dust, debris, and other environmental factors

-

Highlighted Features:

Highlighted Features:- Capacity: Supports loads up to several thousand pounds

- Versatility: Suitable for various industrial applications with adjustable reach

- Construction: Made from high-strength steel for durability and reliability

- Installation: Can be easily installed on concrete floors with a minimal footprint

- Flexibility: 360-degree rotation for maximum range of motion

- Safety: Reduces manual lifting and meets OSHA safety standards

- Productivity: Improves efficiency with smooth and precise load handling

-

Spanco Freestanding Jib Cranes install almost anywhere, including outside. These foundation-mounted, freestanding jibs offer higher capacities, longer spans, and greater rotation than our wall-mounted jib cranes:

Spanco Freestanding Jib Cranes install almost anywhere, including outside. These foundation-mounted, freestanding jibs offer higher capacities, longer spans, and greater rotation than our wall-mounted jib cranes:Features of Spanco 101 Series Freestanding Jib Cranes—Foundation Mounted

- No gussets, freeing up area at foot of crane’s mast

- Square steel plate comes welded to bottom of mast

- The plate positions and plumbs the mast by anchoring to the first-pour concrete footing

- The second pour supports the mast

- 1 (877) 511-6353

- info@mhipros.com

- Locations