-

- Plain or trussed track

- Stainless steel track

- Aluminum track

- Side-mount track

- Curved track accommodates almost any degree curve

- Any color paint, epoxy coatings, or galvanized finish

- Single track, dual track, or multiple tracks

- Mylar® lip seal for heavy dust or paint overspray applications

- Intermediate bumpers can be installed to designate multiple work areas on a single section of track

-

Highlighted Features:

Highlighted Features:- Capacity: Supports loads up to several thousand pounds

- Range of Motion: Dual-arm design with two swivel points for enhanced maneuverability

- Construction: High-strength, durable materials for heavy-duty use

- Installation: Can be mounted on walls, floors, or columns

- Flexibility: Ideal for reaching around obstacles and into confined spaces

- Safety: Reduces manual lifting and physical strain on operators

- Productivity: Improves load handling efficiency and reduces downtime

-

- Rust free & replaceable stainless steel cylinder.

- 100% duty cycle.

- Ideal for working in hazardous areas (explosive environments).

- Temperature rated -20°C to 70°C.

- Insensitive to dust and humidity.

- Designed to conform with ASME 30.7 and FEM Classification 1Bm.

- Designed with a 5:1 factor of safety for lifting.

- Automatic self-adjusting multi disc brake 125% WLL

- Tried and tested Delta P load limiting device set 130% WLL for all CE model (lifting only).

- Spark resistant (Atex Zone 1 & 2).

- Compact design and lowest weight in class.

- Pilot pendant control with emergency shut-off valve or Variable speed toggle control.

- OPTIONAL Declutchable drum on Tugger versions for free spooling.

- Individually load tested before shipment – Delivered with Load Test Certificate.

-

The Ballasted Guardrail System is an unparalleled solution offering exceptional passive safety for both membrane and built-up roof systems. Engineered with precision, this system boasts a plastic-coated steel weighted base that rests gently on the roofing membrane, creating a fully freestanding structure that complies with OSHA standards. Experience the pinnacle of protection for your roof, safeguarding both workers and roofing systems alike. Invest in the Ballasted Guardrail System for unmatched passive safety and peace of mind. Elevate your rooftop safety measures with the modular aluminum guardrail system, renowned for its industry-leading fall protection on hazardous work sites. Its versatile design allows for infinite configurations, complemented by a sleek aesthetic appeal. With a robotically welded rail system, this guardrail can withstand any weather condition, surpassing ANSI and OSHA regulations to provide maximum protection.

The Ballasted Guardrail System is an unparalleled solution offering exceptional passive safety for both membrane and built-up roof systems. Engineered with precision, this system boasts a plastic-coated steel weighted base that rests gently on the roofing membrane, creating a fully freestanding structure that complies with OSHA standards. Experience the pinnacle of protection for your roof, safeguarding both workers and roofing systems alike. Invest in the Ballasted Guardrail System for unmatched passive safety and peace of mind. Elevate your rooftop safety measures with the modular aluminum guardrail system, renowned for its industry-leading fall protection on hazardous work sites. Its versatile design allows for infinite configurations, complemented by a sleek aesthetic appeal. With a robotically welded rail system, this guardrail can withstand any weather condition, surpassing ANSI and OSHA regulations to provide maximum protection. -

Designed for fall protection use and to be connected to existing I-beams. These clamps are adjustable in width and easy to install to most beams. Compliant to all applicable OSHA & ANSI fall protection standards. Installed for temporary or permanent use. Ideal to keep on-site in a ‘fall protection toolbox’ to create a compliant anchor point when needed.

Designed for fall protection use and to be connected to existing I-beams. These clamps are adjustable in width and easy to install to most beams. Compliant to all applicable OSHA & ANSI fall protection standards. Installed for temporary or permanent use. Ideal to keep on-site in a ‘fall protection toolbox’ to create a compliant anchor point when needed. -

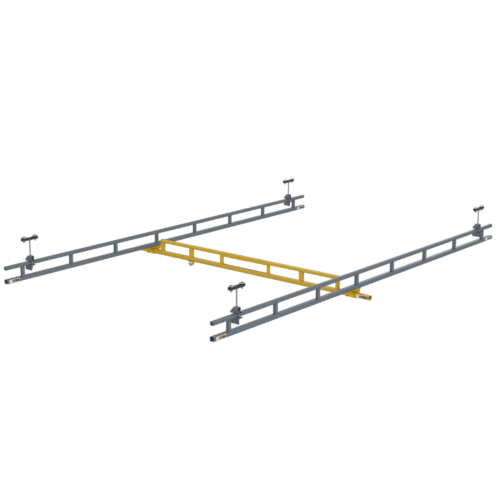

The Palmer Safety BeamGuard HLL Stanchion can be used in combination with any of Palmer Safety’s rope HLL kits and cable HLL kits. Able to accommodate up to two workers between each set of stanchions (maximum stanchion spacing is 60’), the BeamGuard has three base size options to allow for installation onto a variety of beam sizes. A Pass-Through Top Accessory is also available to facilitate 100% tie-off when transitioning between spans.

The Palmer Safety BeamGuard HLL Stanchion can be used in combination with any of Palmer Safety’s rope HLL kits and cable HLL kits. Able to accommodate up to two workers between each set of stanchions (maximum stanchion spacing is 60’), the BeamGuard has three base size options to allow for installation onto a variety of beam sizes. A Pass-Through Top Accessory is also available to facilitate 100% tie-off when transitioning between spans. -

- Single, dual, or multiple tracks for use by one, two, or multiple workers

- Traveling bridge design

- Intermediate bumpers can be used to limit trolley travel between the factory-installed end stops for any reason

- Any color paint, epoxy coatings, or galvanized finish

- Mylar® lip seal for heavy dust or paint overspray applications

-

QUICK FACTS

QUICK FACTS- Massive Lifting Power up to 5,500 pounds (2,500 kg)

- Manual, Drill-Drive, Electric, Hydraulic, or Pneumatic Operation

- New Integral Slewing Drive Allows 360º of Smooth and Easy Rotation

- Available in Three Finishes

- Optional Hydraulic Boom Adjustment Package

- Industry-Leading Warranty

SERIES MODELS- 5FT20

- 5FT25

- 5FT40

- 5FT40H

-

Highlighted Features:

Highlighted Features:- Capacity: Supports loads up to 4,000 pounds

- Smooth Movement: Precision bearings and enclosed track for effortless operation

- Flexibility: Modular design for customizable configurations

- Installation: Ceiling-mounted to maximize floor space

- Ergonomics: Reduces strain and improves operator comfort

- Safety: Complies with OSHA regulations to ensure a safe work environment

-

Elevate stage management and functionality with a selection of manual or powered clew winches, tailored for precise handling of lights, scenery, curtains, and other multi-line loads. These winches are capable of lifting up to 2,500 lbs to heights of up to 40 feet, featuring integrated brakes and lock mechanisms to ensure safety and control in a compact design. The powered models add further convenience with secondary brakes, rotary limit switches, and straightforward push-button operations. Designed to integrate seamlessly into any theatrical rigging system, these clew winches offer a combination of robust performance and ease of use. Their modular design provides the flexibility to choose specific components that meet the unique demands of different staging environments. Constructed from durable, heavy-duty materials, these winches are built to last and come with features that promote long service life and reliability.

Elevate stage management and functionality with a selection of manual or powered clew winches, tailored for precise handling of lights, scenery, curtains, and other multi-line loads. These winches are capable of lifting up to 2,500 lbs to heights of up to 40 feet, featuring integrated brakes and lock mechanisms to ensure safety and control in a compact design. The powered models add further convenience with secondary brakes, rotary limit switches, and straightforward push-button operations. Designed to integrate seamlessly into any theatrical rigging system, these clew winches offer a combination of robust performance and ease of use. Their modular design provides the flexibility to choose specific components that meet the unique demands of different staging environments. Constructed from durable, heavy-duty materials, these winches are built to last and come with features that promote long service life and reliability. -

- Custom heights, spans, and support structures

- Column-mounted, foundation mounted (freestanding), or mounted to a mobile, counterweighted base

- Boom lock (Exception: A boom lock is required for Portable Base Swing Arm systems)

- Single, dual, or multiple tracks for one, two, or multiple workers (except for the two-person capacity Portable Base Swing Arm)

- Intermediate bumpers can be used to limit trolley travel between the factory-installed end stops for any reason

- Any color paint, epoxy coatings, or galvanized finish

- Mylar® lip seal for heavy dust or paint overspray applications

-

Come Along Ratchet Winch Hoists are the ideal, durable tools for a variety of utility applications, including overhead or underground maintenance and construction tasks. These hoists are particularly useful for installing heavy equipment. The inclusion of a pulley block allows for flexible configurations to suit specific application needs, while their compact design enables usage in tight spaces. Additionally, multiple hoists can be connected together to facilitate the movement of heavy components over long distances. Come Along Ratchet Winch Hoists boast an aluminum alloy main frame with an open construction, ensuring easy cleaning and maintenance. Furthermore, the hoists are equipped with safety features that allow the cable to bend or break away in the event of overloading, providing protection for both the user and the equipment.

Come Along Ratchet Winch Hoists are the ideal, durable tools for a variety of utility applications, including overhead or underground maintenance and construction tasks. These hoists are particularly useful for installing heavy equipment. The inclusion of a pulley block allows for flexible configurations to suit specific application needs, while their compact design enables usage in tight spaces. Additionally, multiple hoists can be connected together to facilitate the movement of heavy components over long distances. Come Along Ratchet Winch Hoists boast an aluminum alloy main frame with an open construction, ensuring easy cleaning and maintenance. Furthermore, the hoists are equipped with safety features that allow the cable to bend or break away in the event of overloading, providing protection for both the user and the equipment.

- 1 (877) 511-6353

- info@mhipros.com

- Locations