Highlighted Features:

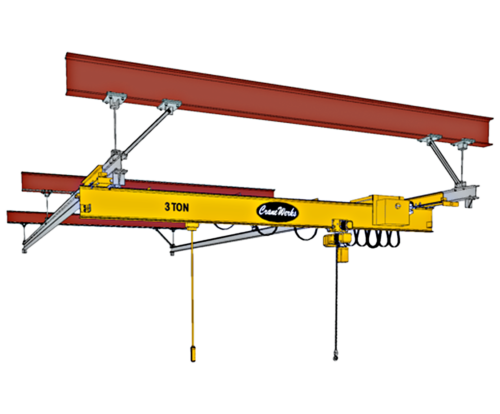

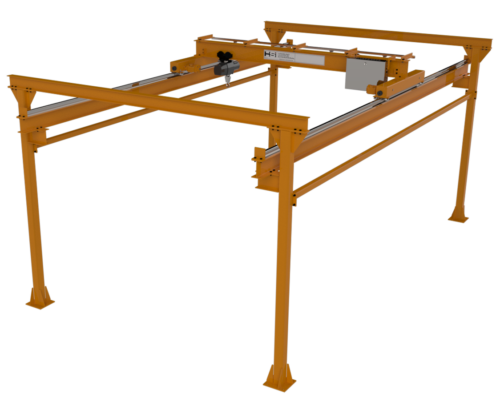

- Capacity: Supports loads up to 15 tons

- Power Source: Electric motors for smooth and precise movement

- Material: High-strength construction for durability

- Mobility: Smooth-rolling casters for easy movement

- Adjustability: Adjustable height and span options

- Efficiency: Improves productivity and reduces physical strain

- Versatility: Suitable for manufacturing, warehousing, and construction

- Safety: Complies with OSHA standards for safe lifting operations