-

Manufactured in South Korea

-

Completely repairable with easy access design (1/4 ton is not repairable)

-

Load tested to 150% of rated capacity

-

Meets ANSI/ASME standards

-

Single-hand control of free-chain function with load brake

-

Low temperature grease functions at -45°C (-49° F)

-

- Standard Hoists are Atex approved, EX II 2 GD IIC T4 (X) / EX II 2 GD IIB T4 (X) / EX II 2 GD IIC T4 (X)

- Copper platings and stainless steel components can be offered for increased spark resistance

- Lubrication free rotary vane motor. – Rust free & replaceable Stainless steel cylinder

- 100% Duty cycle

- Ideal for working in hazardous areas (Explosive environments)

- Temperature Rated -4°F to 158°F

- Insensitive to dust and humidity

- High Grade carbon steel swivel hooks with safety catches.

- Galvanized Grade 80 Load chain made to EN818 standard – 5:1 Design factor of safety

- Automatic self-adjusting multi disc brake 125% WLL.

- Tried and tested slip clutch design load limiting device set 130% WLL.

- Compact design and Lowest headroom in class.

- Anti-climb and Anti-drop devices standard.

- Pilot Pendant control with Emergency shut-off valve

- Compliant with ASME B30-11 and B30-16

-

- 10t ~ 60 ton

- Standard Hoists are Atex approved, EX II 2 GD IIC T4 (X) / EX II 2 GD IIB T4 (X) / EX II 2 GD IIC T4 (X)

- Copper platings and stainless steel components can be offered for increased spark resistance

- Rust free & replaceable Stainless steel cylinder

- 100% Duty cycle

- Ideal for working in hazardous areas (Explosive environments)

- Temperature Rated -4°F to 158°F

- Insensitive to dust and humidity

- High Grade carbon steel swivel hooks with safety latches

- Galvanized Grade 80 Load chain made to EN818 standard – 5:1 Design factor of safety

- Automatic self-adjusting multi disc brake 125% WLL.

- Tried and tested slip clutch design load limiting device set 130% WLL.

- Compact design and Lowest headroom in class.

- Anti-climb and Anti-drop devices standard.

- Pilot Pendant control with Emergency shut-off valve

- Complaint with ASME B30.16

-

- Connecting a power drill directly to the drive mechanism

- Connecting a power drill to the flexible drive shaft

- Using the hand crank directly to the drive mechanism

- Connecting the hand crank handle to the flexible drive shaft

- Standard product is attached with powershaft 5ft, a bit and a handle

- Lifting speed meets the below specifications when r.p.m. of cordless driver drill is 1,300.

- Please apply 15.6V cordless driver drill to EHMF-38.

- Do not use electric or pneumatic impact driver.

-

- 1t ~ 6 tons

- Overload Protection Safety Device, Standard on 1t Capacity and Greater

- A High Quality Urethane Paint

- Heavy Duty Single Braid Wire Reinforced Air Hose with Swivel Fittings on each end

- Galvanized Load Chain for Corrosion Resistance

- Meets ASME B30.16 standards

- Pendant Control Machined from Solid Brass for Corrosion Resistant and Spark Resistance with an Emergency Stop Button. Available in Aluminium as well.

- Upper Hook with a Safety Factor of 5X the Nominal Load

- Low-maintenance lubrication free Rotary Vane Motor for clean use within Food Grade, Petrochemical, and Pharmaceutical Environments

- Heat Treated and Rust-Free Motor Components with Removable Stainless Steel Cylinder, Allow for Operational Longevity and Low Cost Replacement

- Air Valve is 100% Nickel Plated inside and out for Corrosion Resistance.

- Infinitely Variable Speed Via Pull Cord Control

-

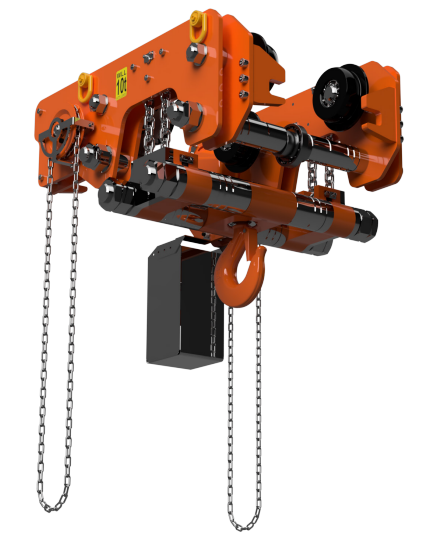

Experience the versatility and efficiency of Ultra Low Headroom Hoists, designed for demanding industrial lifting applications where space is limited. These hoists combine the functionality of a hoist and trolley, making them ideal for ultra-low headroom requirements. With load capacities ranging from 0.5 to 40 tons, these hoists are built to handle heavy lifting tasks. The corrosion-resistant load chain and hand chain ensure durability and reliable performance. The adjustable design allows for easy fitting to various beam widths, and the wheels are compatible with both I-beams and H-beams. Safety features include anti-drop plates and an overload protection safety device. Spark-resistant units are also available upon request, catering to specialized environments. Discover the power and flexibility of Ultra Low Headroom Hoists for your industrial lifting needs. With their compact design, durability, and safety features, these hoists provide efficient and reliable lifting solutions in tight spaces.

Experience the versatility and efficiency of Ultra Low Headroom Hoists, designed for demanding industrial lifting applications where space is limited. These hoists combine the functionality of a hoist and trolley, making them ideal for ultra-low headroom requirements. With load capacities ranging from 0.5 to 40 tons, these hoists are built to handle heavy lifting tasks. The corrosion-resistant load chain and hand chain ensure durability and reliable performance. The adjustable design allows for easy fitting to various beam widths, and the wheels are compatible with both I-beams and H-beams. Safety features include anti-drop plates and an overload protection safety device. Spark-resistant units are also available upon request, catering to specialized environments. Discover the power and flexibility of Ultra Low Headroom Hoists for your industrial lifting needs. With their compact design, durability, and safety features, these hoists provide efficient and reliable lifting solutions in tight spaces. -

- Ultra-low profile design

- Tight headroom

- Hoist and hand geared / push type combo

- Articulated design for special beams

- Can accommodate beams with abnormally aggressive curves

- Dual pivoting points on the trolleys allow for smooth navigation of the beam

- Corrosion-resistant packages are available

- Marine-grade finishes are available

- Spark resistant features are available